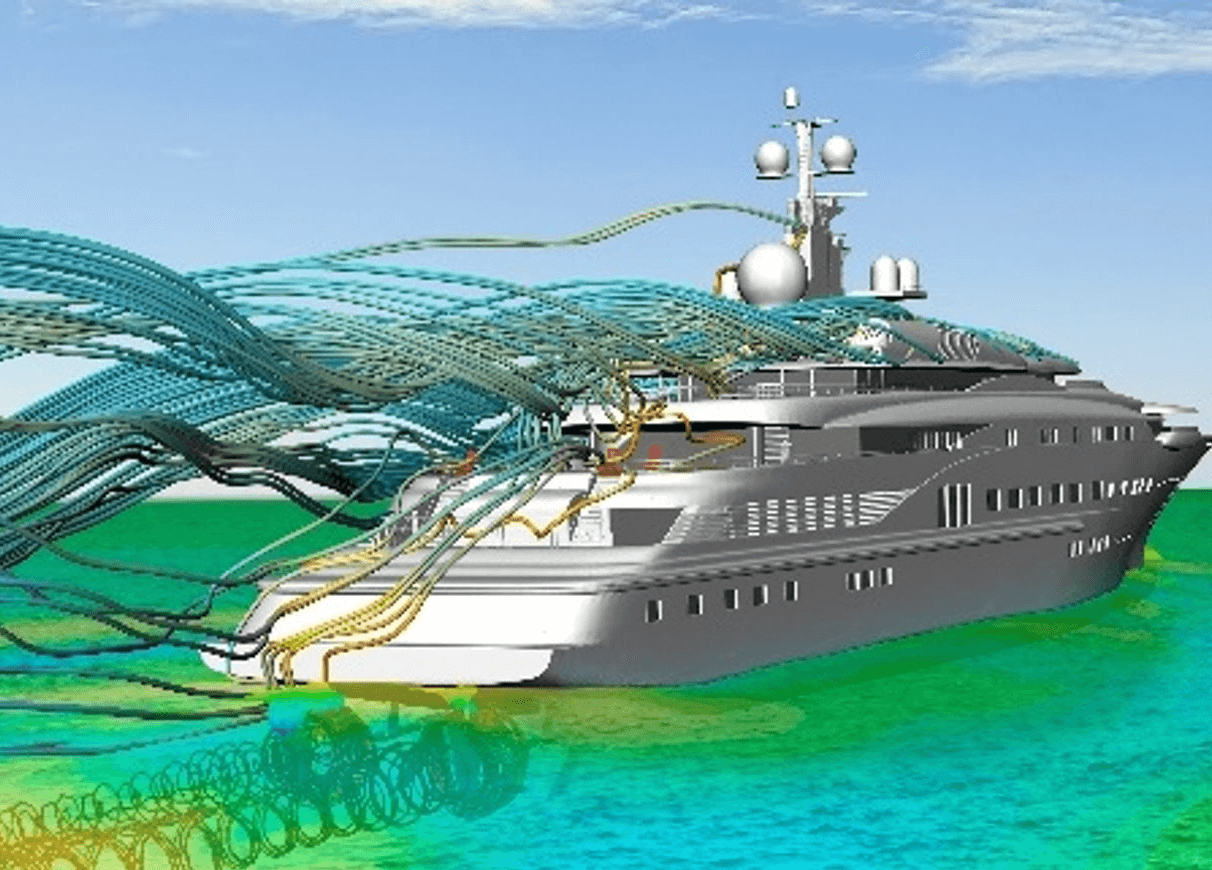

Simcenter STAR-CCM+ is the CFD-focused Multiphysics engineering solution that uniquely integrates comprehensive physics with intelligent design exploration in a single CAD-to-solution environment.

It is build for the most simple to the most advanced CFD simulation needs. The solution offers powerful flow solvers that are easy to set up and are robust, accurate and deliver excellent scalability.

Simcenter STAR-CCM+ uniquely brings automated design exploration and optimization to the CFD simulation toolkit of every engineer.

The single integrated environment includes everything from CAD, automated meshing, multiphysics CFD, sophisticated postprocessing, and design exploration. Some benefits include:

- Reduced wall clock time thought robust pipelined simulation workflow.

- Increased simulation throughput allow engineering groups to evaluate more designs faster and more accurately.

- Leverage market leading design space exploration tools to discover better designs faster.

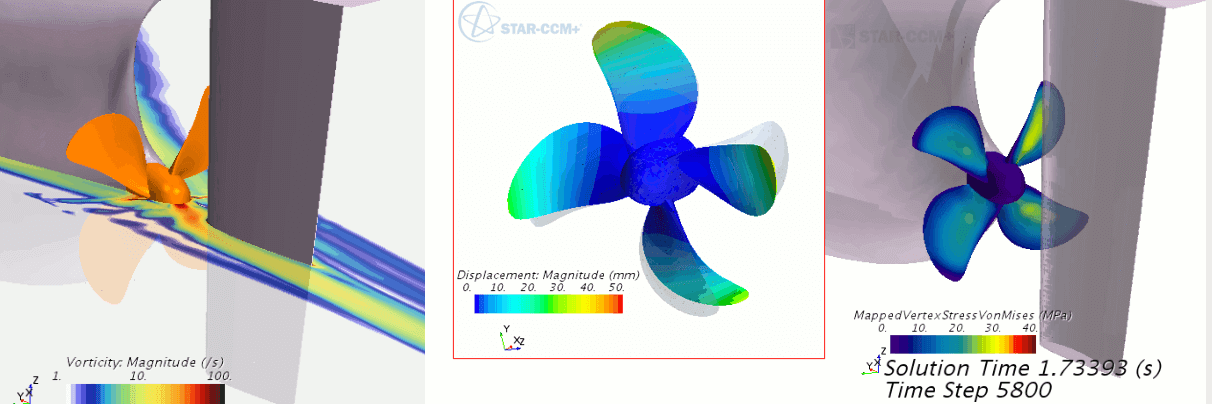

- Marine, Shipbuilding and Offshore

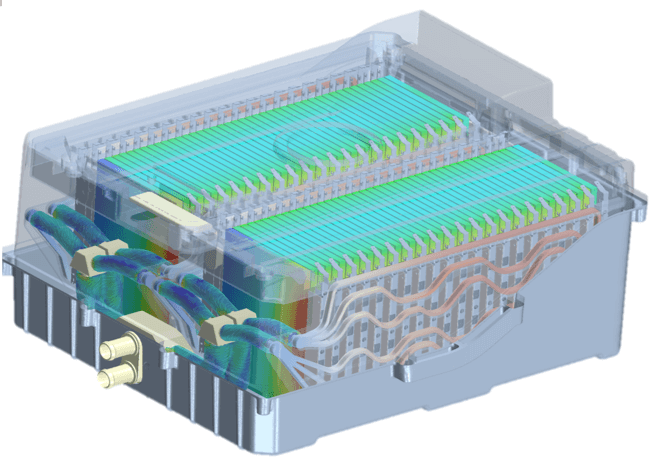

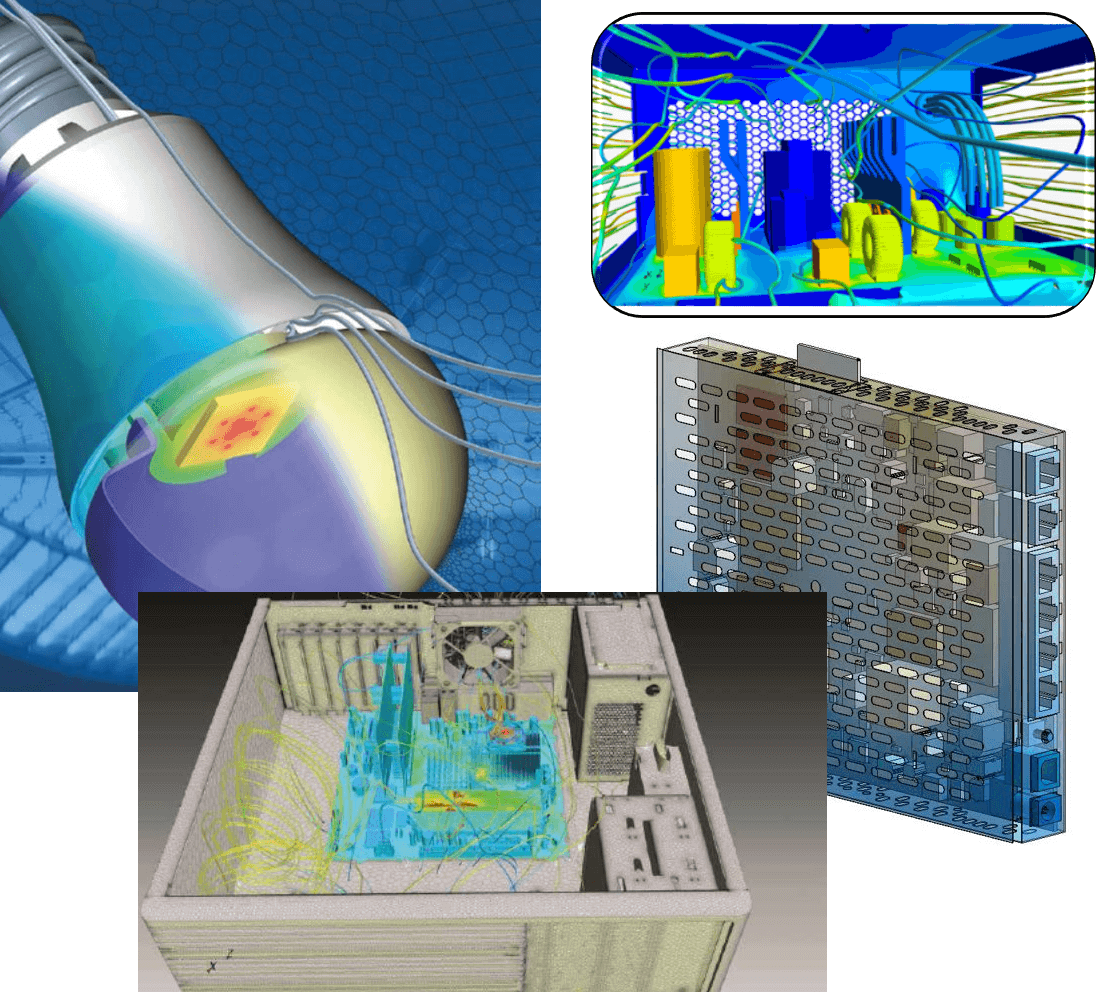

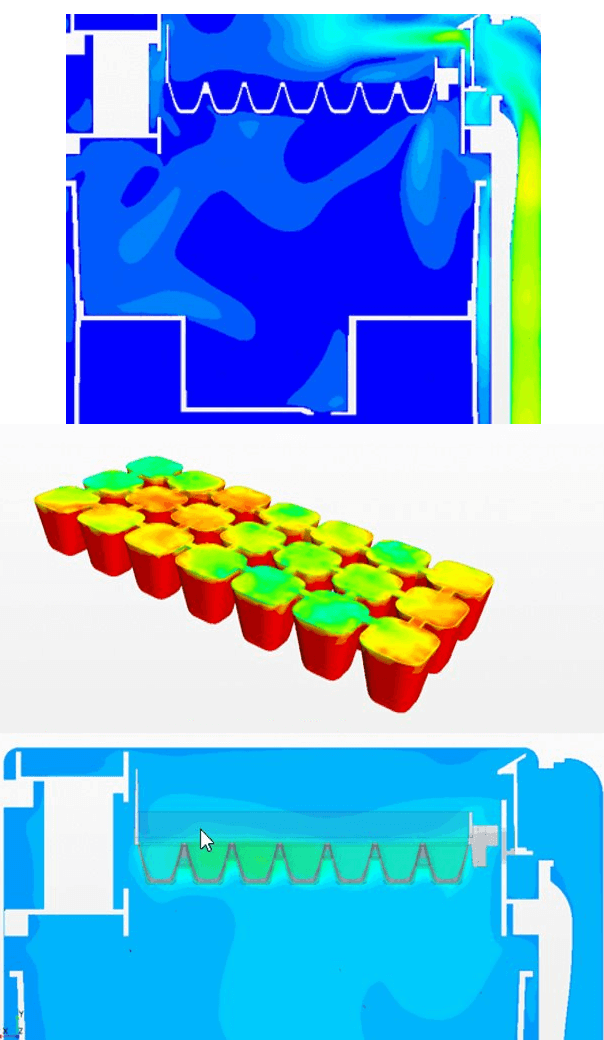

- Electronics

- Manufacturing & Consumer Products

- Multiphysics

- Aerospace and Defence

- Design Exploration

- STAR-CCM+ Customers

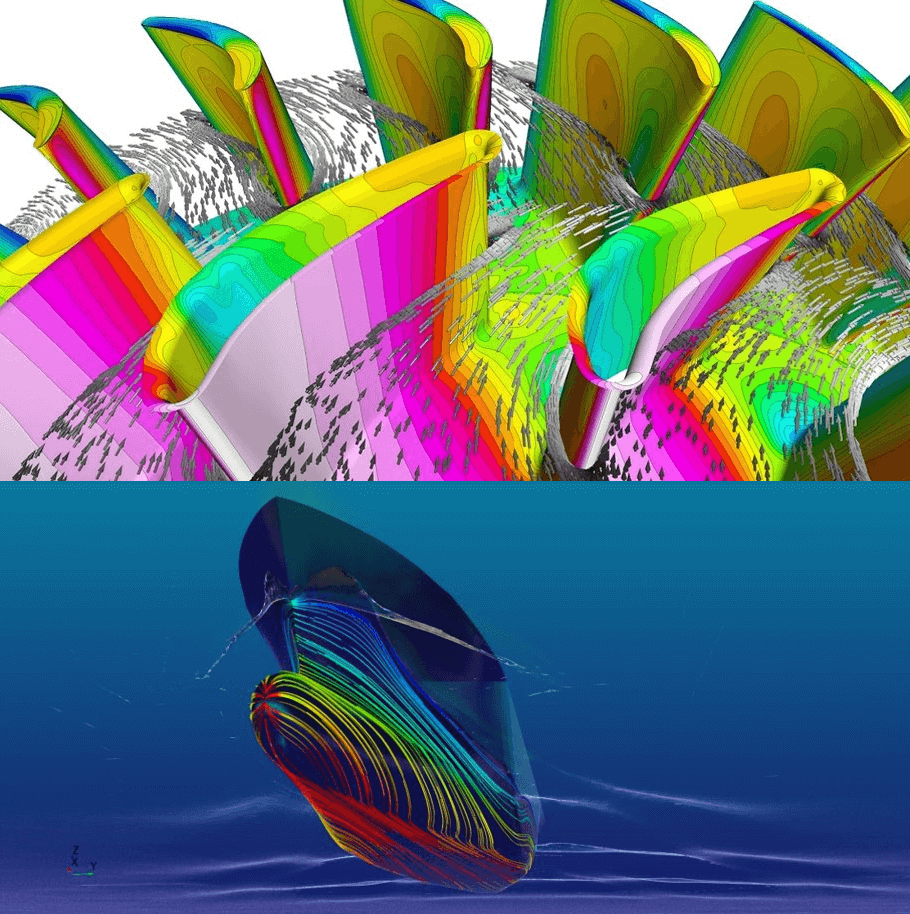

3D simulation has the ability to simulate multiphase flow in a 3D environment with no need for assumptions based on empirical data. Star-CCM+ provides fluid velocity, pressure, temperature, gas composition and other variables throughout the solution domain for problems with complex geometries and boundary conditions.

As part of the analysis, an engineer may change the geometry of the system or the boundary conditions and observe the effect of these changes on fluid flow patterns or distributions of other variables, such as gas composition.

Simcenter STAR-CCM+ is designed to handle simple as well as complex problems and large model sizes. It has been used by our industrial partners for calculations numbering billions of computational cells far beyond the size of any electronics-cooling problem.

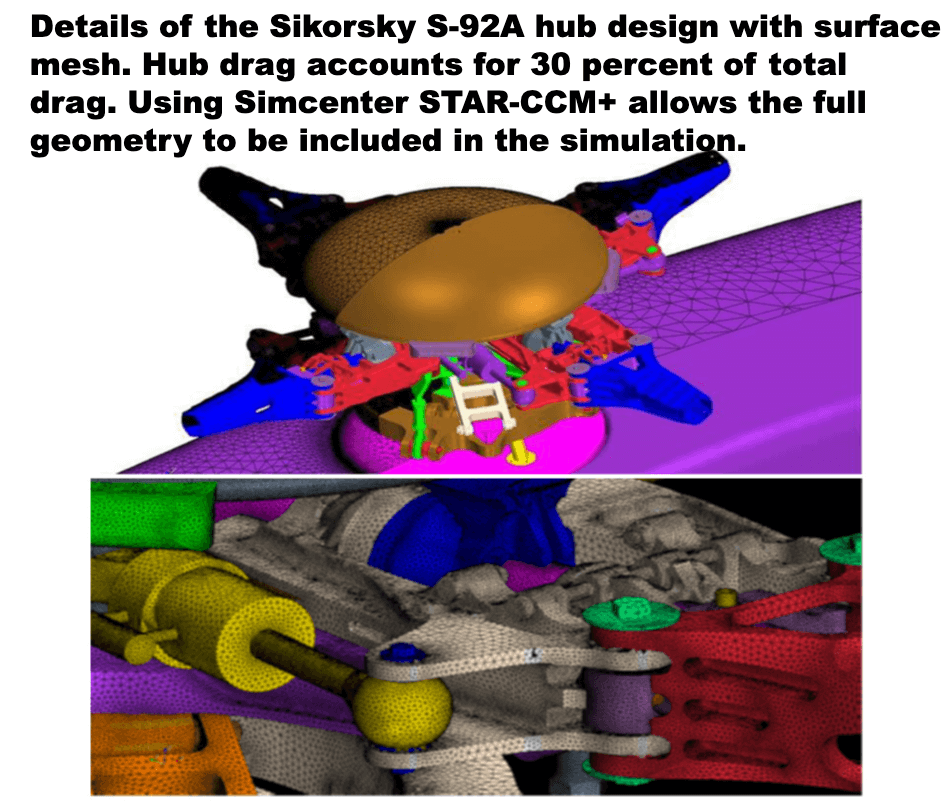

The Simcenter STAR-CCM+ surface wrapper is a tool that creates a geometric representation by shrink-wrapping a high-resolution surface on the complex aspects of the geometry. It allows the user to ignore many of the inadequacies of the 3D model and create a geometric representation that is ready for simulation.

STAR-CCM+ Benefits include:

• Accelerate electronics thermal simulation

• Increase model building efficiency

• Import complex geometry from external systems

• Support fast, scalable computations

• Facilitate broad-based design exploration for optimal results

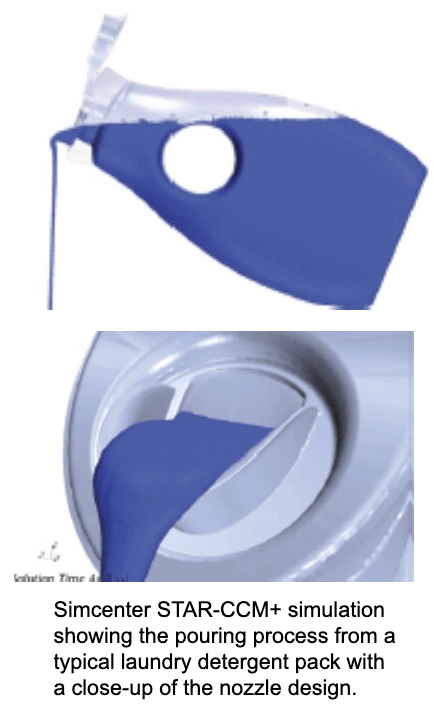

The consumer products industries involve highly complex physico-chemical phenomena – multiphase flows, chemical reactions, heat and mass transfer. Flows are laminar as well as turbulent with Newtonian and highly viscous non-Newtonian fluids. Fluid-fluid interactions play a crucial role. Chemical reactions also occur due to electrothermal and electromagnetic forces. The processes become more complex as these interactions are scale-dependent.

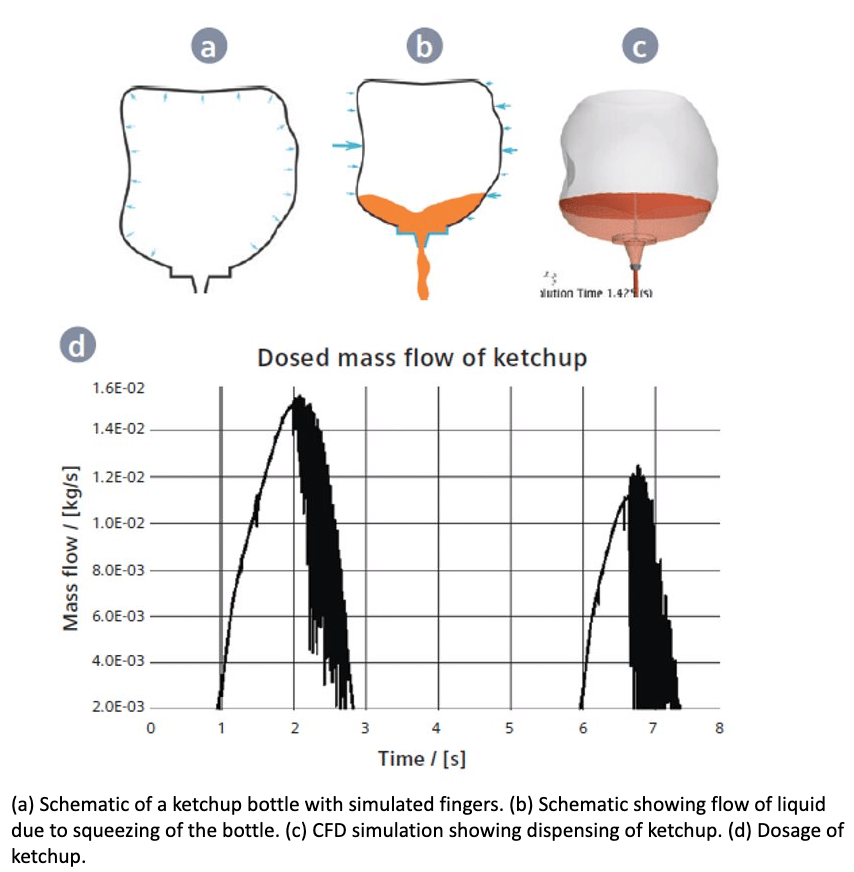

Dosing from a ketchup bottle. Dosing rate can be calculated using fluid flow and structural simulations that can account for the structural behavior of the packaging as well as the non-Newtonian fluid behavior of the ketchup. Such a framework can be utilized to create a rapid prototyping workflow for designing new packaging for product launches.

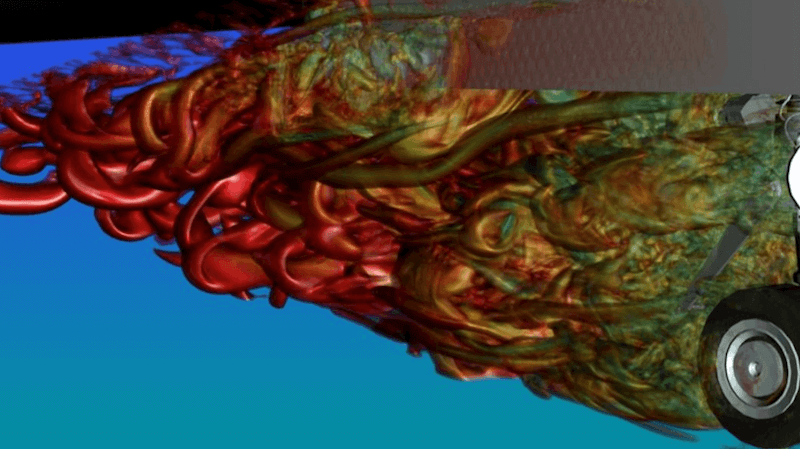

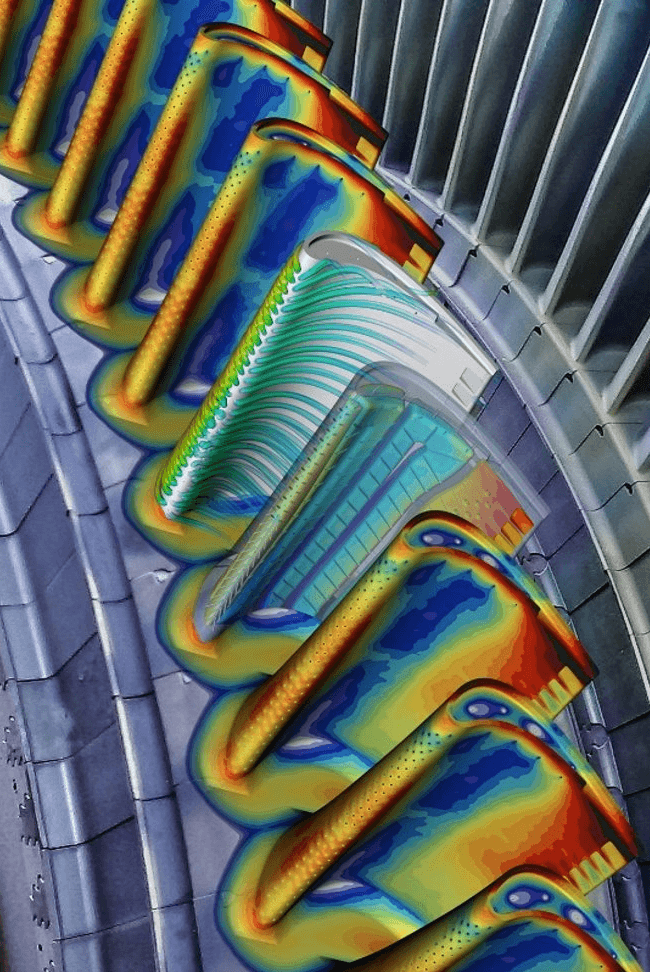

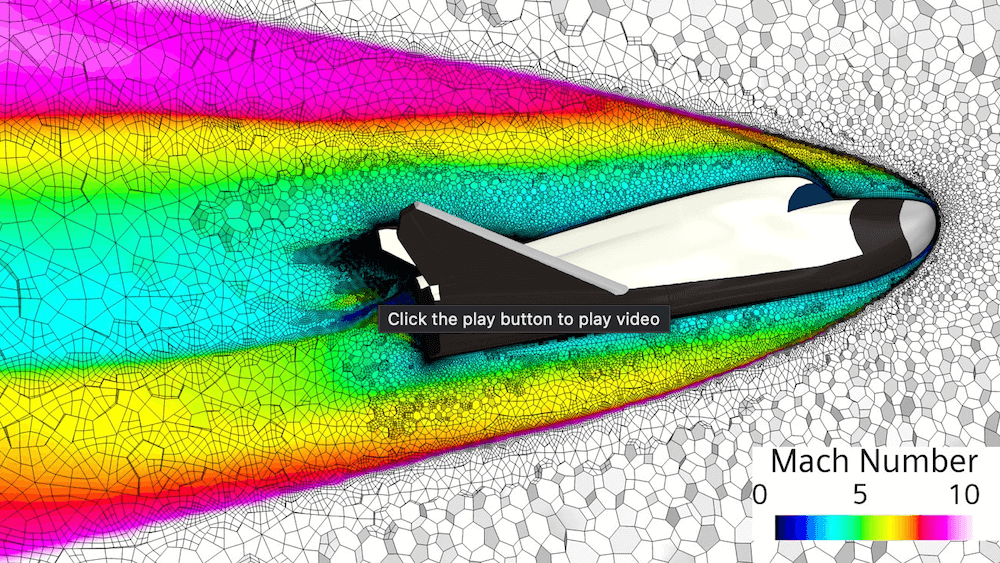

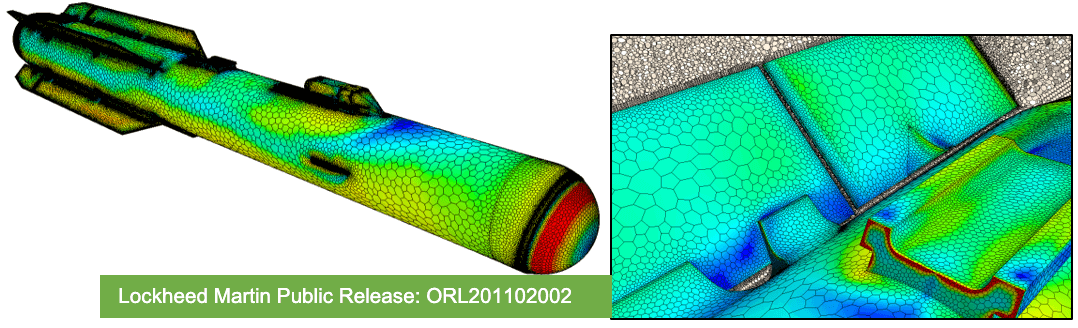

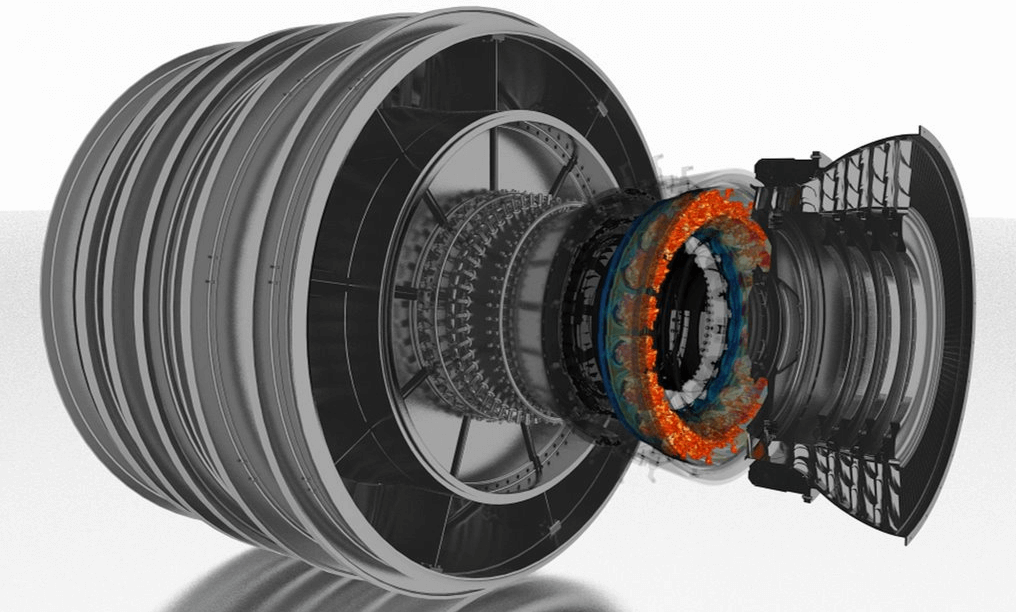

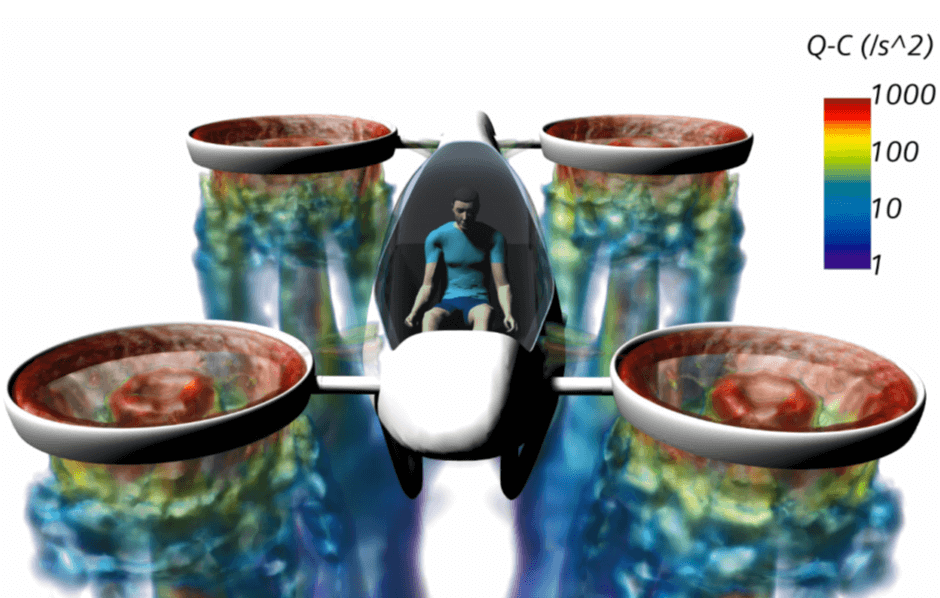

Simcenter™ STAR-CCM+™ software, is a part of the Xcelerator™ portfolio, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software. It can be applied to a wide range of external aerodynamics problems, but it offers aerospace and defense organizations much more than that.

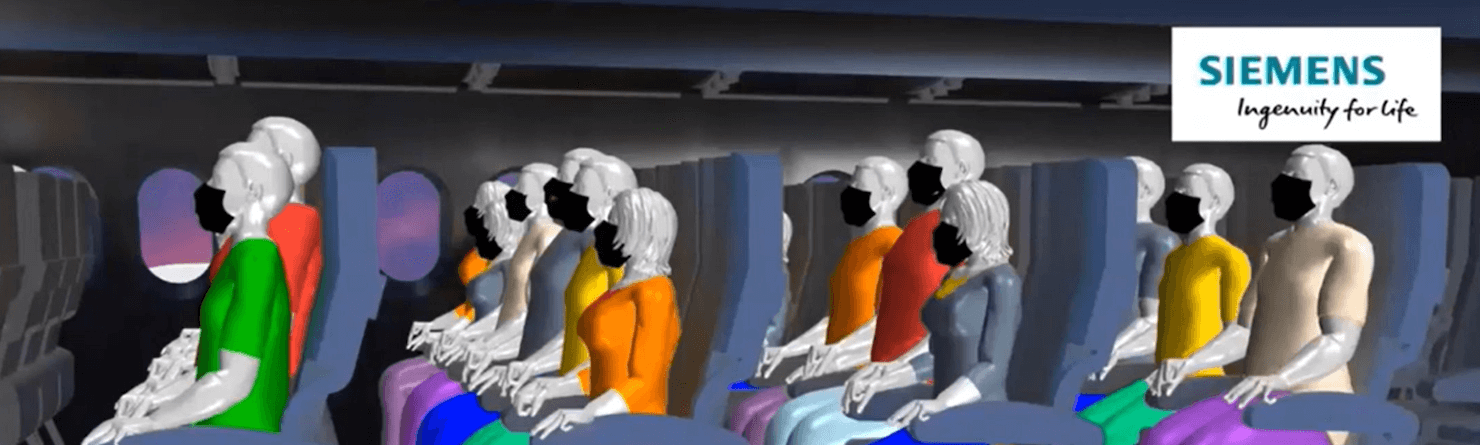

The same software that computes the aerodynamic database can be used for propulsion integration studies, tank sloshing simulations, avionics cooling, e-powertrain analysis and cabin comfort modeling.

The modern CFD solution facilitates the following capabilities:

- Model the full geometry and physics needed to predict real-world aerodynamic performance including influences from propulsion systems, control surfaces and landing gear

- Minimize engineering time and manual work to set up, run and post process aerodynamics simulations

- Automate all steps in the simulation process to quickly generate aerodynamic databases and investigate a full range of design configurations

• Shorten time-to-solution with parallelization and efficient computational algorithms designed for modern high-performance computing (HPC) systems

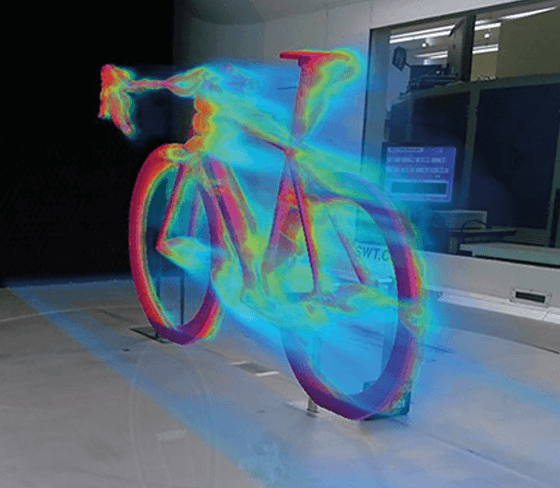

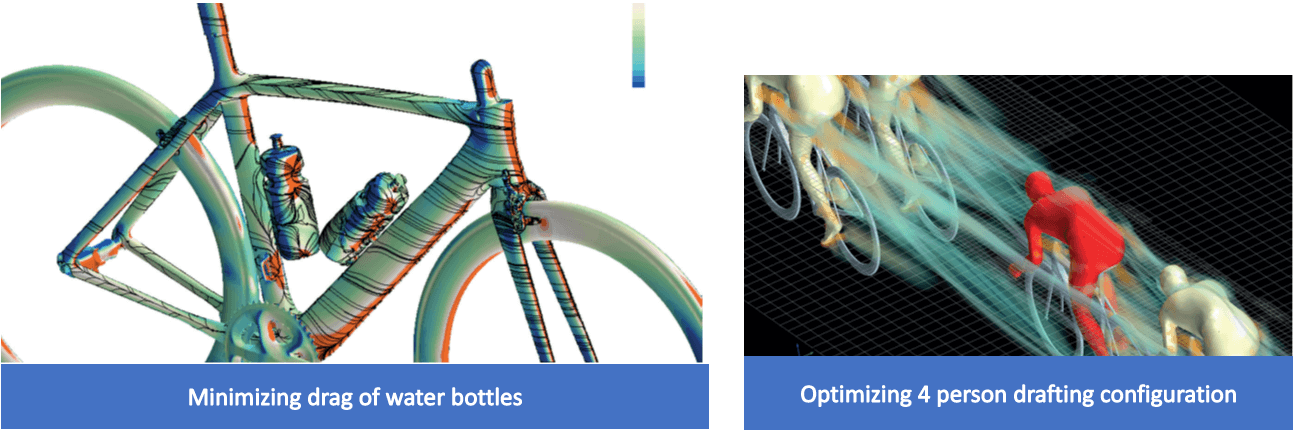

With Simcenter STAR-CCM+, design exploration is also a fully integrated component of the platform, meaning the complexities of stringing multiple tools together are removed. If you know how to run a single simulation with Simcenter STAR-CCM+, you can easily run 100s as it leverages the all-in-one platform, automated meshing, pipelined workflow and physics within Simcenter STAR-CCM+ to overcome the complexities that have historically prevented many from using CFD simulation in this manner.

STAR-CCM+ design exploration process is very different as it uses multiple search strategies simultaneously, and it dynamically adapts to the problem as it learns about the design space. What this means is that exploring the design space requires fewer iterations than other methods and there is no need to be an expert or make decisions about which search strategy use. All you need to do is specify the number of evaluations you want to conduct – based on the time and budget you have – and the intelligent search will make the decisions for you to get you to a better design.