The Trend

- Sustainability

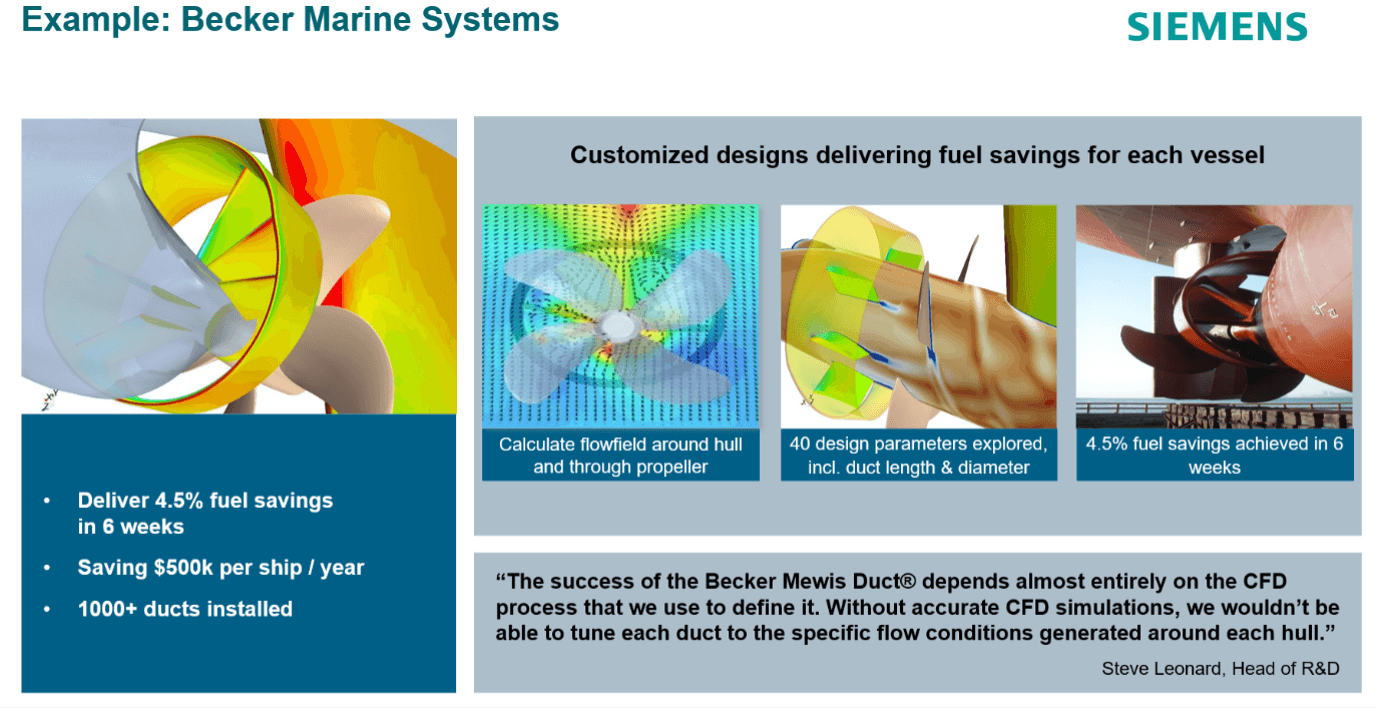

Shipping Industry is one of the main contributors to the global emissions, currently estimated at around 3% of global total. This is why shipping has come in the crosshair of demands for greater efficiency. In COP26, there will be focus on discussing ways to reduce emissions. No surprise that Sustainability is the biggest trend affecting marine industry. Ship designers and builders will definitely face increasing pressure to reduce environmental Impact. Traditional design methods rely on scale model testing and/or model scale CFD simulations. These cannot deliver the level of improvement required in the short timeframes set by governing bodies.

- Global Competition

In marine industry history, we are aware of the up and down cyclical behaviour. When the industry is at the downcycle, ship owners and operators are looking to invest in most cost effective vessels. This means shipyard must compete harder than ever before to develop and build ships with lower total lifecycle costs (both CAPEX and OPEX), higher operational availability and shorter time to market.

- Increasing demand for high value-added vessels

We are seeing an increasing demand for high value-added vessels, multi-role or muti-purpose vessels (especially in the naval, mega yachts and offshore markets), and a growing interest in autonomous shipping (especially in the commercial and naval sectors.)

Therefore ships today are more complex than ever before:

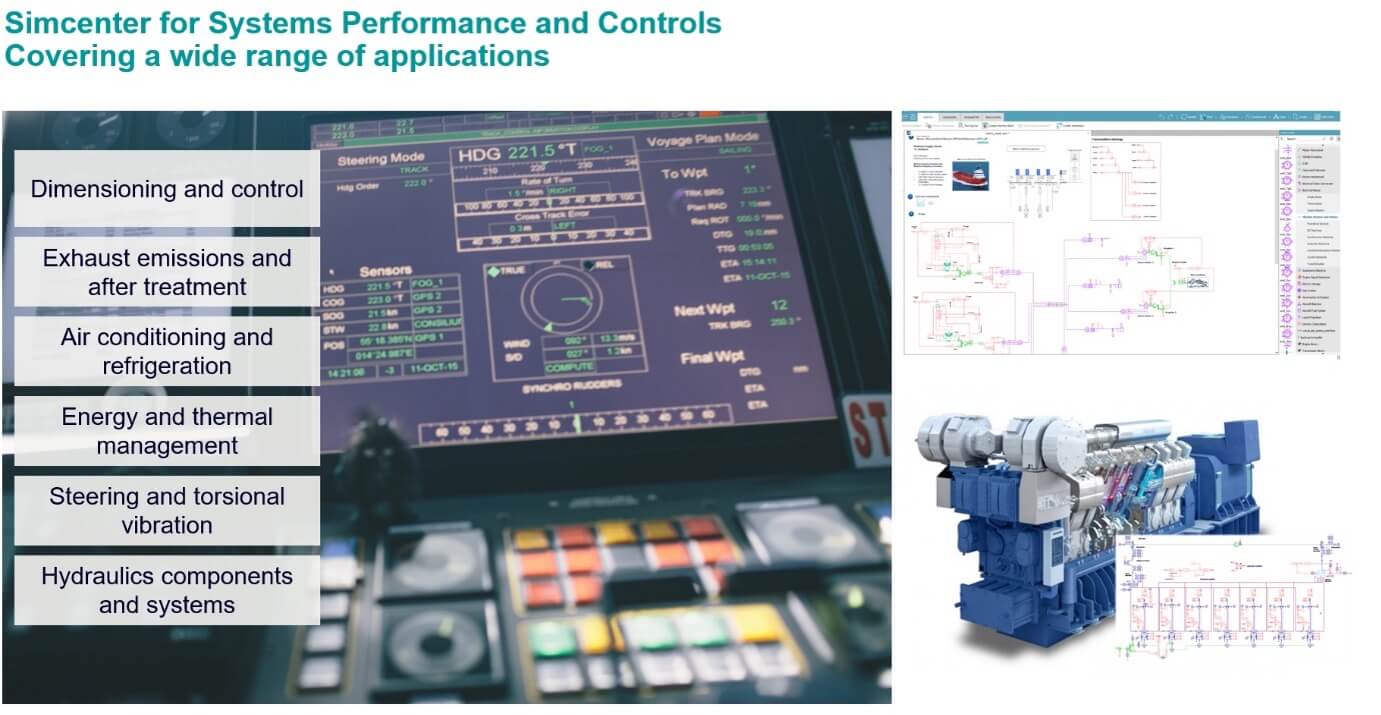

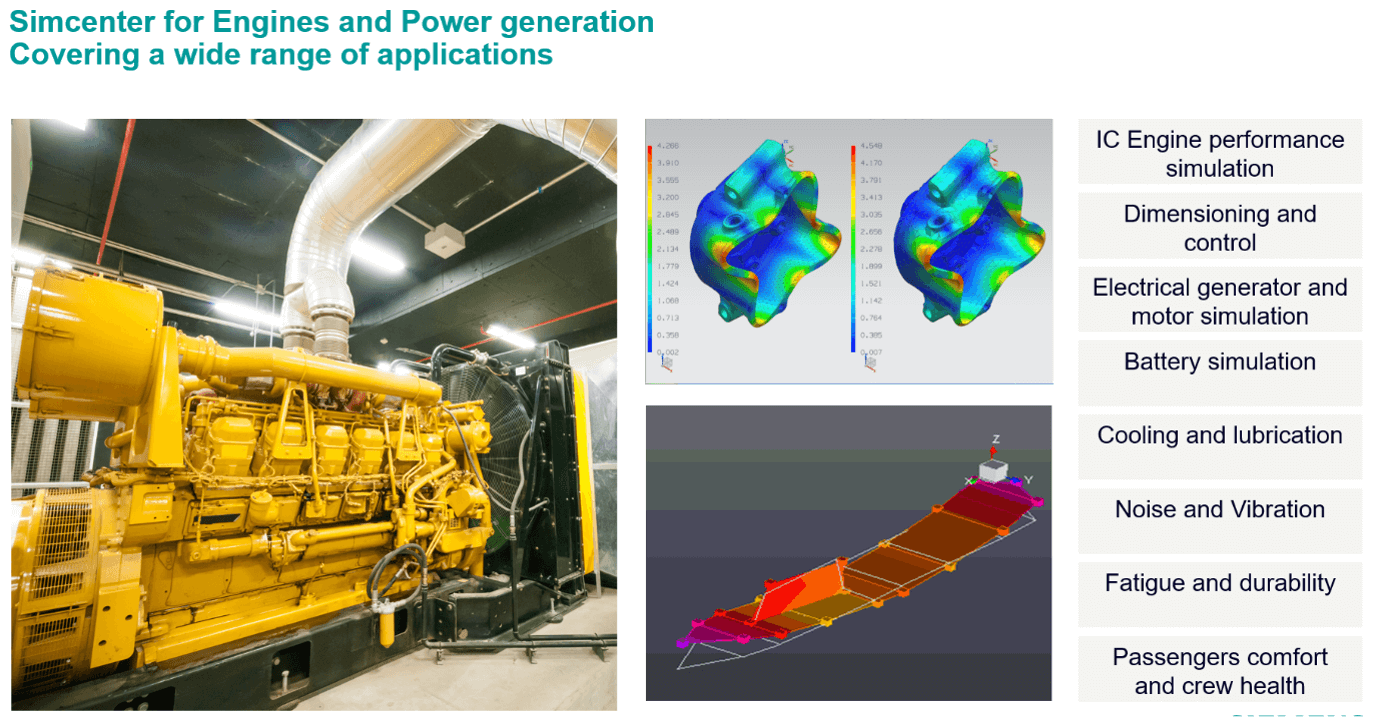

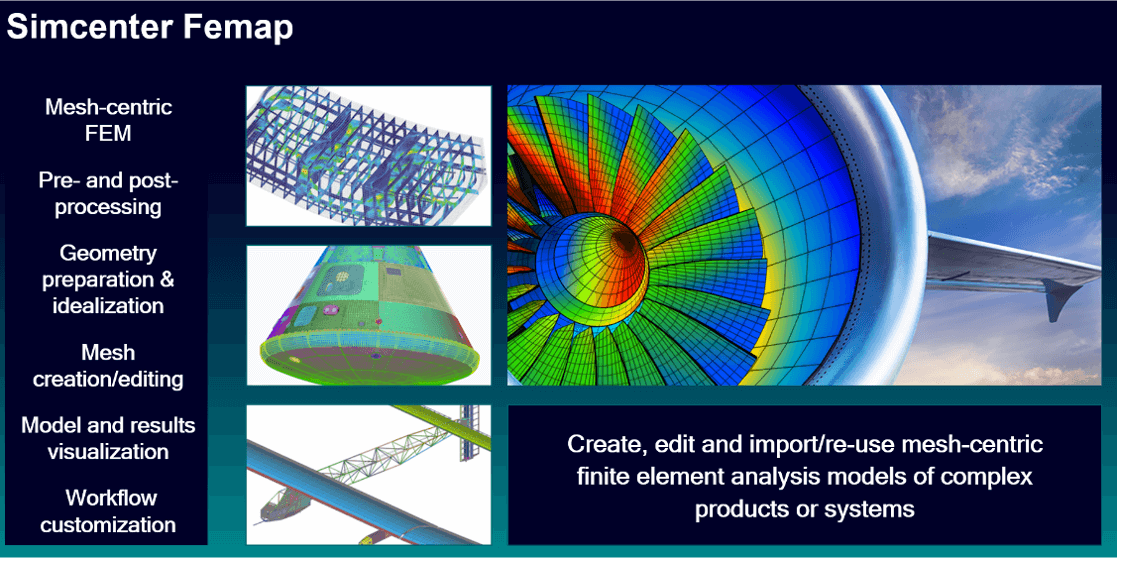

- More complex equipment and systems onboard

- More electrical systems: more sensors, cables etc.

- More parties involved and more information manage and communicate

- Workforce needs to continuously adapt and embrace new technologies